How a solo-built real-time VFD monitoring system quietly prevents hardware failures, reduces downtime, and generates millions of data points for predictive maintenance — all while costing less than a cup of coffee per year.

The Problem: Too Little, Too Late

At Amazon fulfillment centers, motors quietly power the movement of millions of packages. But when one fails — often due to an overloaded or overheating Variable Frequency Drive (VFD) — the impact isn’t small.

A single failure can cause:

n

-

Thousands in equipment damage

-

Disrupted package flow

-

Scrambled technician response

-

Escalations that burn time and money

n

I was the Control Systems Lead during the launch of a new Amazon site. The tech stack was impressive. The visibility into VFD health? Practically nonexistent.

If a VFD tripped or ran hot, we didn’t know until someone spotted a problem after it happened. That wasn’t good enough. So I built a tool that would watch every motor — in real time.

n

The Solution: Real-Time VFD Monitoring

I designed and built an app that runs in the background 24/7, monitoring every VFD across the building. Here’s what it does:

n

-

Reads 500+ VFDs every 2 seconds

-

Uses multithreading to parallelize polling by control cabinet

-

Filters out false positives like inrush spikes

-

Sends Slack alerts only if overload >110% persists for 6+ seconds

-

Avoids alert spam by waiting 5 minutes before repeating on the same tag

-

Stores all data in AWS S3 for trend analysis and future audits

-

Costs only ~$0.06/month to operate

n

What It Looks Like in Action

When a VFD crosses the overload threshold, the app automatically sends a Slack alert like this:

⚠️ VFD Overload Detected

Tag: 8xxxxx | Cabinet: CCxxx

Load: 117% | Amps: 4.6

Time: 2025-05-07 10:03:50

n

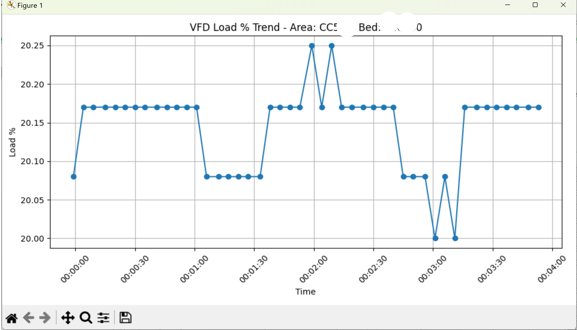

This goes straight to the PDM team, who can open the Trend Viewer tool I built alongside it. They simply enter the VFD tag and time window to see the load % over the last minute, hour, or day — with no need for manual trend extraction or CSV gymnastics

With just a few clicks, they can:

- Enter the VFD tag number and ID (from the alert)

- Select a time window: 1 min, 5 min, 30 min, 1 hr, 24 hrs, or custom

- Instantly visualize load % trends

- Get VFD’s physical location in the building

- Identify spikes, dips, or patterns leading up to the alert

- Export the graph for reporting or escalation with one click

No manual CSVs. No log file digging. Just fast, visual diagnostics the moment they’re needed.

n

This seamless integration means overloads are no longer mysteries — they’re data-driven events with instant visibility. That’s the power of combining real-time alerts with on-demand historical insights..

n

The Impact: Quiet Savings, Big Numbers

This system:

- Prevents 2–3 failures/month on average

- Saves $1,500–$3,000 per failure in equipment

- Enables data-driven maintenance

- Logs 2.4M+ data points/week for engineering analysis

- Costs ~$0.06/month(AWS S3 + PUTs within Free Tier) n

📊 Estimated Annual Savings: $100K–$115K+

And that’s in just one building.

n

Why I Built It (Alone)

I didn’t have a team or a project budget. Just a problem no one had time to solve — and the skills to fix it myself.

I used Python, multithreading, Slack’s API, and AWS’s free tier to design something that could:

- Run quietly and reliably

- Stay out of people’s way

- Only speak up when something mattered

Most of all, I built it so technicians wouldn’t be left guessing after something failed.

Final Thoughts

I didn’t build this system for recognition — I built it because I was tired of preventable failures, delayed escalations, and engineers like me working in the dark.

It started as a background app on a designated PC. Now, it’s monitoring hundreds of motors in real-time, sending smart alerts, generating millions of data points, and quietly preventing over $100K in losses every year — all from a single building.

This is what automation should be: fast, low-cost, invisible until it’s needed, and built with empathy for the people using it.

And if you’re an engineer solving similar problems with limited resources:

n

Don’t wait for approval. Don’t wait for the perfect tech stack.

Build it anyway.

The views expressed here are my own and do not represent my employer