Found your Raspberry PI Pico in a cupboard that you opened 2 years before… Get along with this project to make a line follower robot using Raspberry Pi Pico and a few other Stuff

What is a Line Follower Robot?

A line follower is a type of autonomous robot that can detect and follow a line drawn on the floor, typically a black line.

Components Required

| Component | Quantity | Notes |

|—-|—-|—-|

| Raspberry Pi Pico | 1 | Use the Pico H for easier pin access |

| BFD-1000 IR sensor array / any 5 array IR sensor Module | 1 | To detect the Black Line |

| L298N motor driver | 1 | To drive motors precisely |

| BO Motors (3–12V) | 2 | Preferably 12V ones 🙂 |

| Bo motor Wheels | 2 | Wheels For Bo Motor |

| Caster wheel (free wheel) | 1 | To balance the front |

| LiPo Battery (12V) | 1 | Or any regulated 12V source |

| Wires, breadboard, etc. | As needed | For connections |

| Computer | 1 | For programming and debugging |

Cooking the Pi🍳

The Software Part

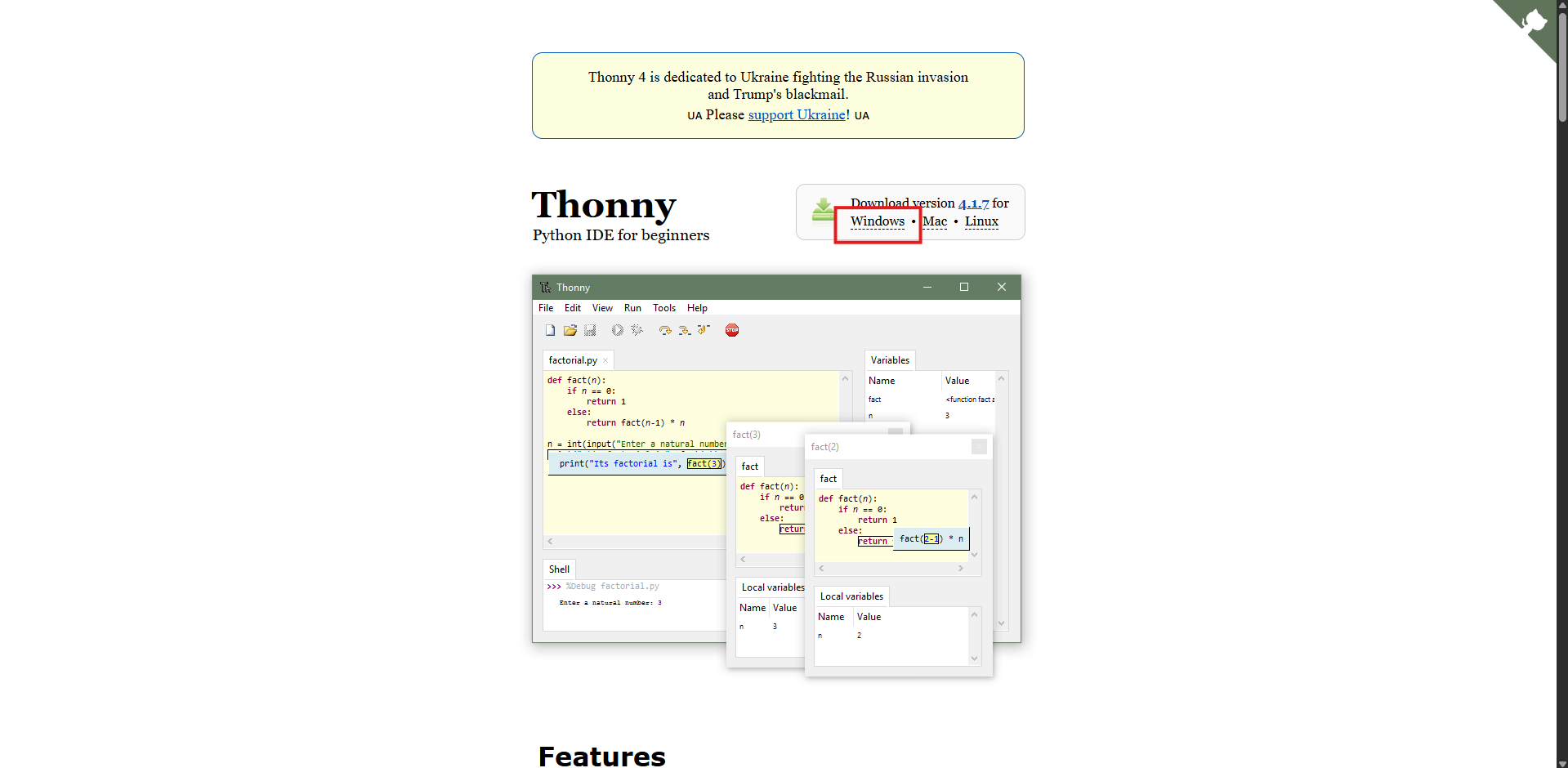

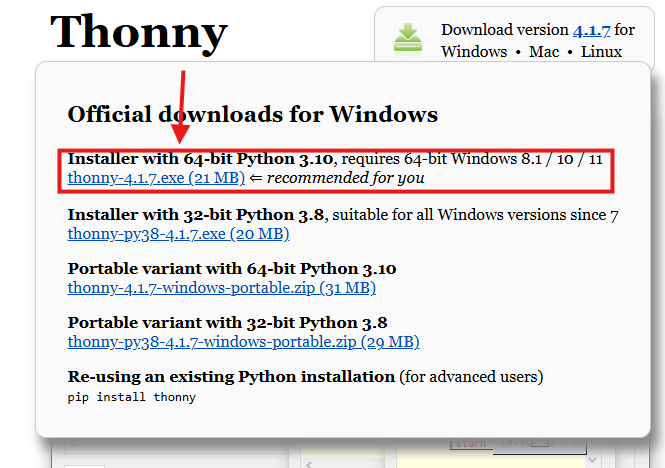

1. Installing Thonny IDE

-

Visit: thonny’s Website

-

Download it for your OS (Windows/Mac/Linux).

-

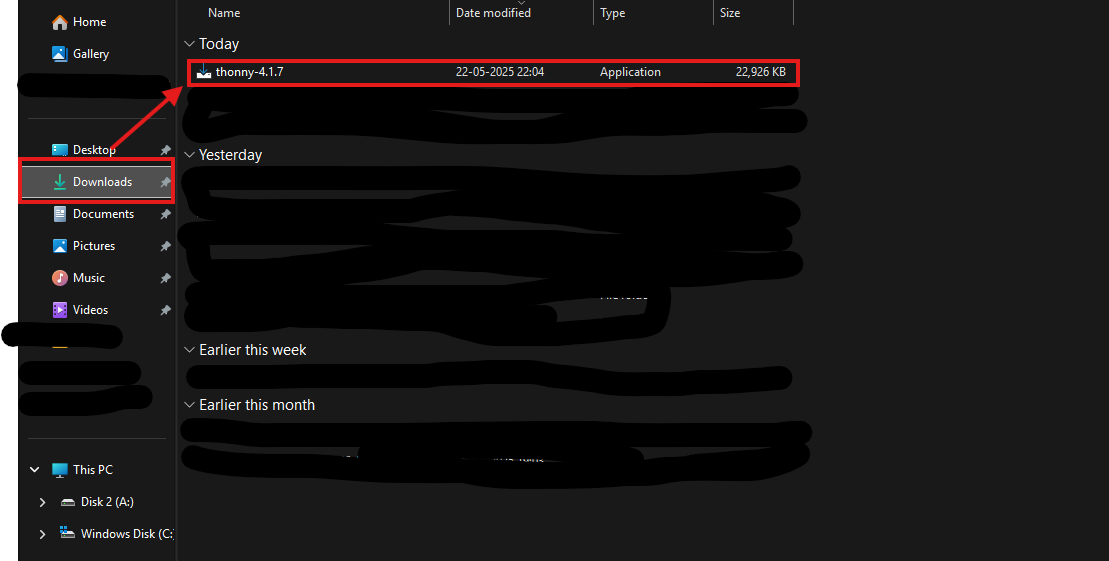

Navigate to the Downloads folder after the .exe file has been downloaded in File Explorer

-

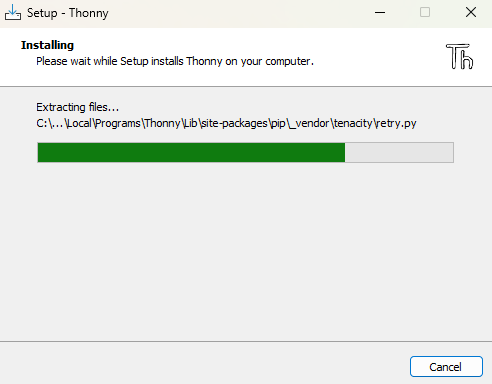

Then click on the .exe file (thonny-4.1.7.exe) to execute the application and click on next until you see that the thonny is being installed

Flashing the pico with Micropython Firmware

:::info

If you have already flashed the micropython firmware the you can skip to next part

:::

Plug in your Pico while holding the BOOTSEL button.

- It appears as a USB drive.

- Go to micropython.

uf2[ file]() download for Pico - Download

.uf2the file and copy it to the Pico USB drive. - Pico will reboot into MicroPython.

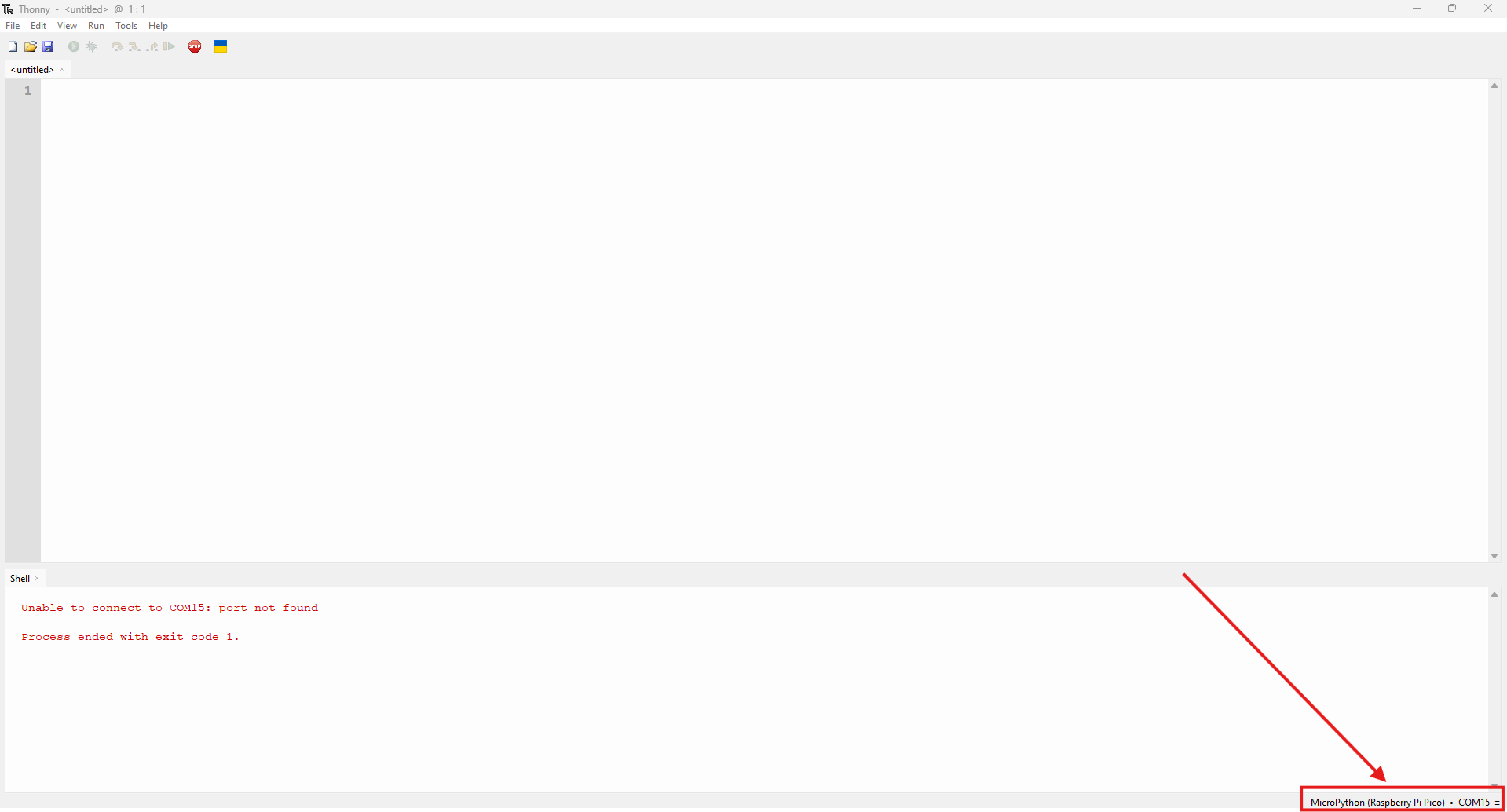

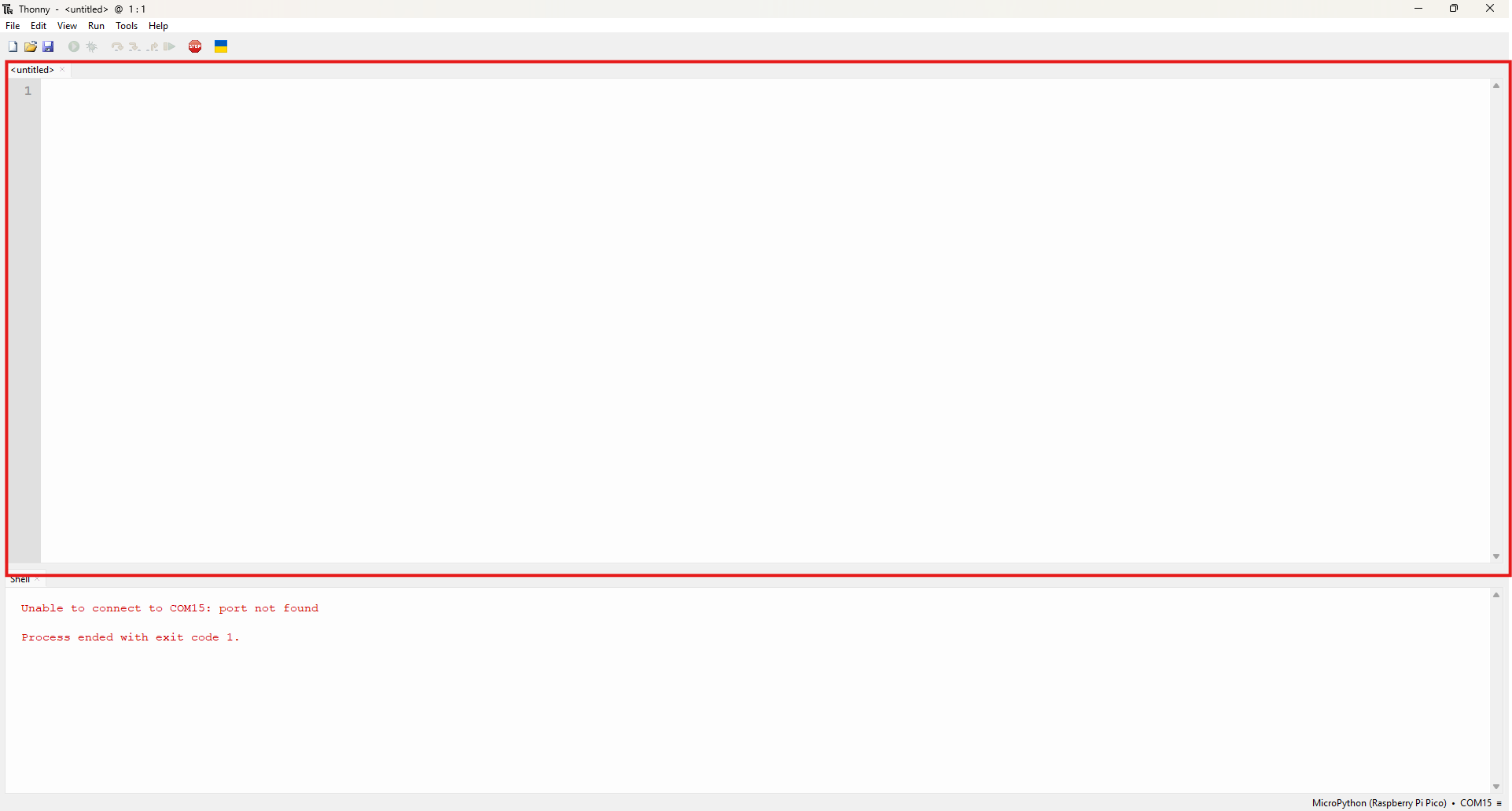

Set up Thonny

-

Open Thonny

-

Go to Run > Select Interpreter > MicroPython (Raspberry Pi Pico)

-

Select the right port.

-

Paste the following MicroPython code into the script area

Get code here or paste the code below

from machine import Pin, PWM

import time

# Motor Pins

in1 = Pin(2, Pin.OUT)

in2 = Pin(3, Pin.OUT)

in3 = Pin(4, Pin.OUT)

in4 = Pin(5, Pin.OUT)

ena = PWM(Pin(6))

enb = PWM(Pin(7))

ena.freq(1000)

enb.freq(1000)

# Sensor Pins

sensors = [Pin(i, Pin.IN) for i in range(8, 13)]

# Speed Settings

BASE_SPEED = 35000 # Slow and safe for normal movement

MAX_SPEED = 40000 # Max PWM limit

TURN_SPEED = 25000 # Slower speed for turning

# PID Settings

Kp = 8000 # Proportional gain, tune this as per your bot

Ki = 0

Kd = 0

# PID Variables

previous_error = 0

integral = 0

# Motor control functions

def set_motor_speed(left_speed, right_speed):

left_speed = max(0, min(MAX_SPEED, left_speed))

right_speed = max(0, min(MAX_SPEED, right_speed))

if left_speed == 0:

in1.low()

in2.low()

else:

in1.high()

in2.low()

if right_speed == 0:

in3.low()

in4.low()

else:

in3.high()

in4.low()

ena.duty_u16(left_speed)

enb.duty_u16(right_speed)

def stop():

in1.low()

in2.low()

in3.low()

in4.low()

ena.duty_u16(0)

enb.duty_u16(0)

# Read sensor values

def read_sensors():

return [s.value() for s in sensors]

# Calculate position (PID error calculation)

def calculate_error(sensor_values):

weights = [-2, -1, 0, 1, 2]

total = 0

count = 0

for i in range(5):

if sensor_values[i] == 0: # Line detected (assuming black line)

total += weights[i]

count += 1

if count == 0:

return None # Line lost

return total / count

# PID controller

def pid_control(error):

global previous_error, integral

if error is None:

return 0, 0 # No correction needed if line is lost

integral += error

derivative = error - previous_error

correction = int(Kp * error + Ki * integral + Kd * derivative)

previous_error = error

return correction, correction

# Smart Search with PID

def smart_search():

global previous_error, integral # Reset PID variables for search

previous_error = 0

integral = 0

for attempt in range(5):

print("Search attempt", attempt+1)

# Turn left (using PID control)

in1.low()

in2.high()

in3.high()

in4.low()

ena.duty_u16(TURN_SPEED)

enb.duty_u16(TURN_SPEED)

time.sleep(0.5)

stop()

time.sleep(0.1)

sensor_values = read_sensors()

error = calculate_error(sensor_values)

left_correction, right_correction = pid_control(error)

if 0 in sensor_values:

print("Found line after left turn")

return

# Turn right (using PID control)

in1.high()

in2.low()

in3.low()

in4.high()

ena.duty_u16(TURN_SPEED)

enb.duty_u16(TURN_SPEED)

time.sleep(1.0)

stop()

time.sleep(0.1)

sensor_values = read_sensors()

error = calculate_error(sensor_values)

left_correction, right_correction = pid_control(error)

if 0 in sensor_values:

print("Found line after right turn")

return

print("Failed to find line after searching.")

# Main loop

while True:

sensor_values = read_sensors()

print("Sensors:", sensor_values)

error = calculate_error(sensor_values)

if error is None:

print("Line lost, starting search")

stop()

smart_search()

else:

correction = int(Kp * error)

left_speed = BASE_SPEED - correction

right_speed = BASE_SPEED + correction

set_motor_speed(left_speed, right_speed)

time.sleep(0.01)

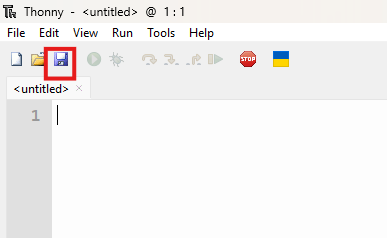

Click on the save icon

-

You will get a Prompt stating:-

Where do you want to save

1)Raspberry Pi Pico

2)To this PC

-

Choose Pico and save the file as

main.pyotherwise it will not auto-run on when powered on

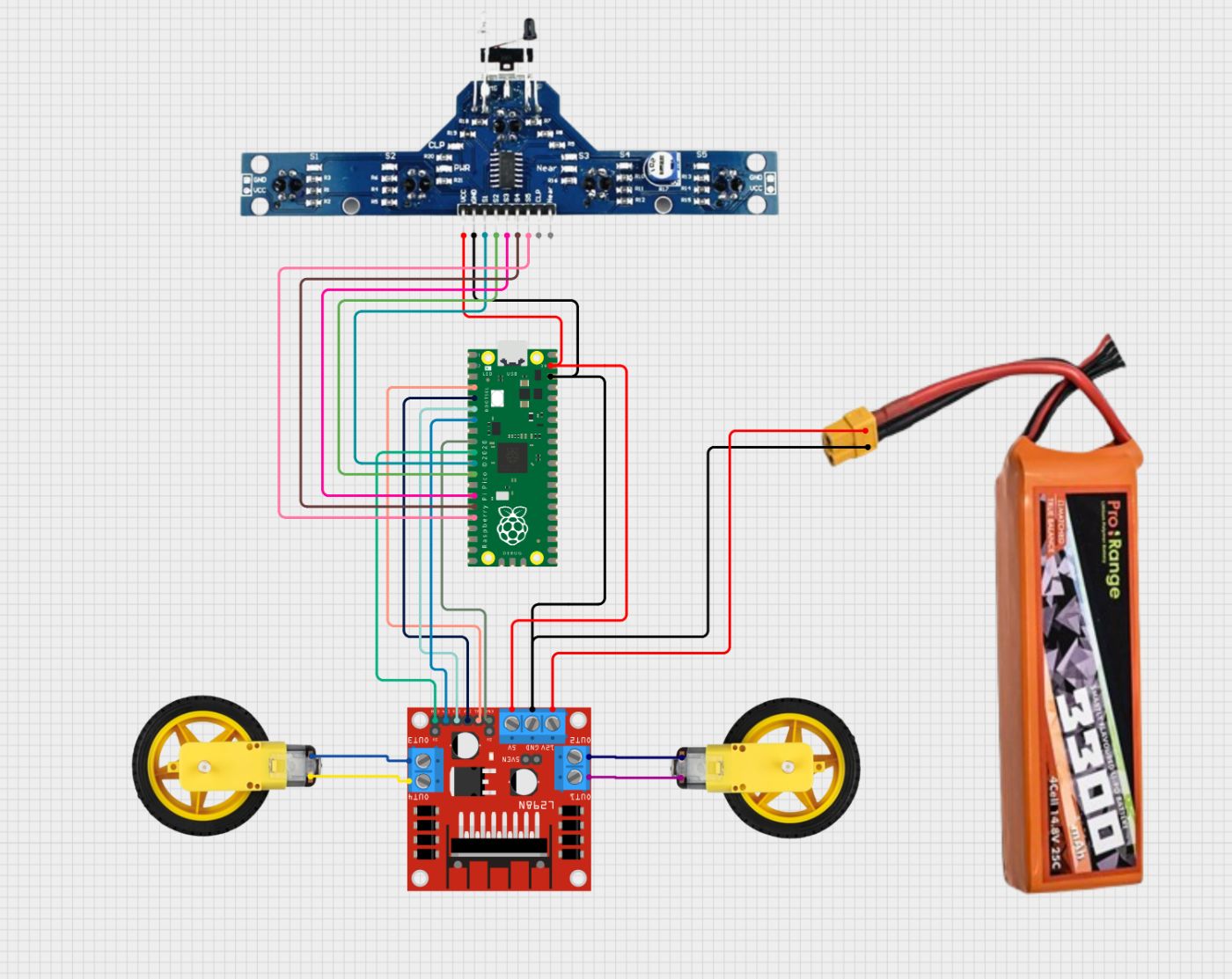

The Hardware part

Connections

Here is a link for the line follower connections:- Click Here

Connection Table

L298N to Pico

| L298N Pin | Connects To |

|—-|—-|

| IN1 | Pico GP2 |

| IN2 | Pico GP3 |

| IN3 | Pico GP4 |

| IN4 | Pico GP5 |

| ENA | Pico GP6 (PWM) |

| ENB | Pico GP7 (PWM) |

| VCC | 12V from the battery |

| GND | Pico GND & battery GND |

| 5V | V_Sys pin |

BFD 1000 to Pico

| IR Sensor Pin | Connects To (Pico Pin) | Function |

|—-|—-|—-|

| OUT1 | GP8 | Left-most sensor |

| OUT2 | GP9 | Left sensor |

| OUT3 | GP10 | Center sensor |

| OUT4 | GP11 | Right sensor |

| OUT5 | GP12 | Right-most sensor |

| VCC | 5V | Power |

| GND | GND | Ground |

IR Sensor Calibration

-

Run your line follower code in Thonny.

-

You should see values being printed in the following format corresponding to each sensor:-

Sensors: [x, x, x, x, x] -

Place the bot on a white surface. You should see:

[1, 1, 1, 1, 1](white reflects IR = HIGH). -

Move the centre sensor over the black line. You should see:

[1, 1, 0, 1, 1](black absorbs IR = LOW). -

Slide the bot side to side across the line. All sensors should detect black (

0) when over a line. -

Adjust potentiometers (if needed) on the IR sensor for reliable

0/1switching.

Test Run Video

Drive Link:-https://drive.google.com/file/d/1ODuU0T4gvLMk8YIl7x5UDorZBtHX7OeK/view?usp=sharing

That’s all, folks, for this project

Meet you in another tutorial like this

Thanks,

Shivank Dan